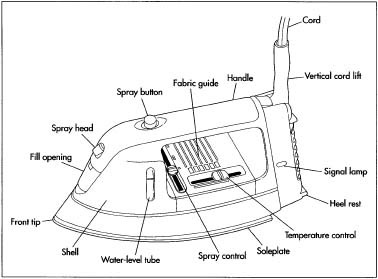

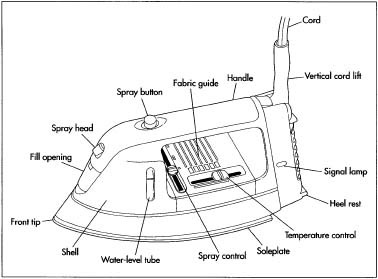

construction of a iron box

1. Bakelite handle

handle of a iron box used for holding it.The handle can be made either with wood or with plastic. The handle is attached to the cover plate with the aid of screws. Studs can also be used for this purpose

LAMP GLOWING it indicates temperature is within predetermined value current is flowing

lamp is not glowing temperature is more than predetermined value current is not flowing

3.steel cover

steel cover of the iron box

1. Bakelite handle

handle of a iron box used for holding it.The handle can be made either with wood or with plastic. The handle is attached to the cover plate with the aid of screws. Studs can also be used for this purpose

2.Pilot

Lamp

The pilot lamp is housed in the cover plate of

the electric iron. One end of the pilot lamp is connected to supply, while the

other end is connected to the heating element. A shunt resistance is provided

across the pilot lamp which assists in providing a voltage drop. The shunt is

designed to provide a voltage drop of 2-5 voltsLAMP GLOWING it indicates temperature is within predetermined value current is flowing

lamp is not glowing temperature is more than predetermined value current is not flowing

3.steel cover

steel cover of the iron box

4.Sole

Plate

The sole

plate is the thick, triangular-shaped slab of iron that forms the base over

which the electric iron is built up. The bottom surface and edges are heavily

chromium plated, to prevent it from rusting. The base plate should hold the

iron pressure plate and cover plate in position. For this purpose we can see

two or sometimes three studs in the base plate. These studs aid in holding the

position of cover plate and pressure plate.

5.Pressure

Plate

This plate is generally called the top plate as

it follows the shape of sole plate. The pressure plate has some holes through

which the studs form the base plate passes through. We should tighten the nuts

on the studs in such a way that the pressure plate and sole plate are pressed

tight against each other. In some iron the pressure plate is heavy and made of

cast iron while in some other cases, it is a thin sheet of steel, about ¼ cm

thick

6.The

Heating Element

The

heating element is present between the sole plate and pressure plate. It is

pressed hard between the two plates. The heating element consists of nichrome

wire wound around a sheet of mica. The two ends of the nichrome wire are

connected to the contact strips. The contact strips are connected to the

terminals of the iron. There are two reasons for which mica is chosen in the

heating material. Mica is a very good insulating material. Besides that mica

can also withstand very high temperatures. The entire assembly of mica sheet,

nichrome wire and contact strips are riveted together resulting in a

mechanically sound and robust construction. There is an asbestos sheet, which

separates and thermally insulates the top plate from the heating element.

7.The Cover

Plate

The cover

plate is made of thin sheet of iron. It is placed on top of the base plate and

it covers all the internal parts of the iron. The handle and connector are only

attached to the cover plate.

No comments:

Post a Comment